Annals of Mathematics and Physics

Mathematical Model Calculation of Loading of Wheels Pair of Diesel Locomotive UzTE16M at Wheel-shoe Braking

Department “Locomotives and locomotive establishment”, Faculty Railway transport engineering Tashkent State Transport University, Russia

Author and article information

Cite this as

Sherzod F, Obidjon K. Mathematical Model Calculation of Loading of Wheels Pair of Diesel Locomotive UzTE16M at Wheel-shoe Braking. Ann Math Phys. 2025;8(5):177-180. Available from: 10.17352/amp.000162

Copyright License

© 2025 Sherzod F, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.Abstract

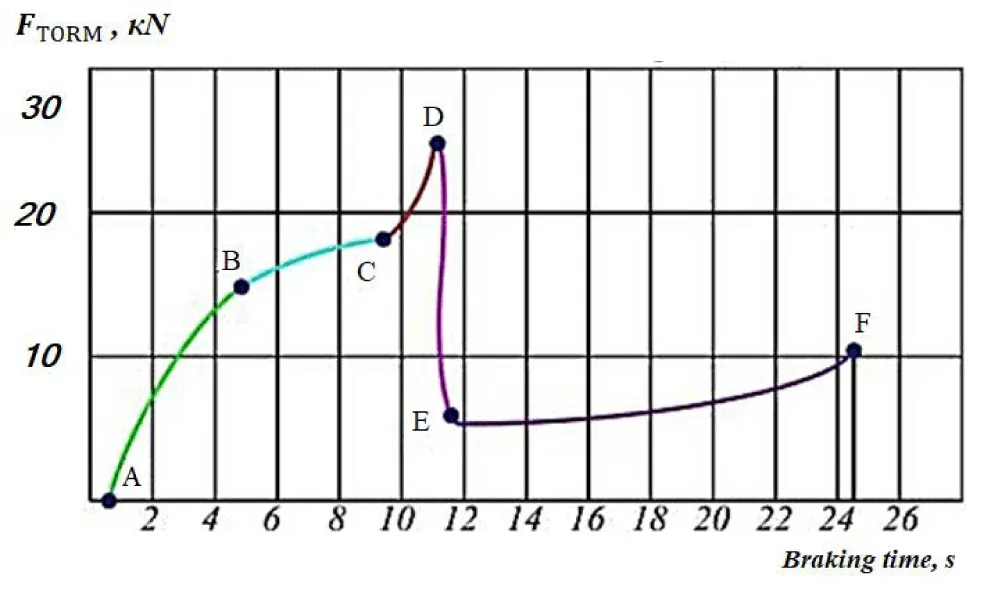

This article examines the calculation of the locomotive's wheelset load during wheel-blade braking. In this case, the bandage, together with the wheel center and the wheel axle, forms rigid joints, the deformations of which are not taken into account. As an example for the methodology, the UzTE16M2 locomotive strap was used, and a curve for the change in the braking force FTORM during the clogging of the wheelset was presented.

The traditional material for brake shoes of rolling stock for many decades has been grey friction cast iron, which has proven itself as a relatively reliable material under conditions of friction without lubrication on steel [1]. Recently, shoes have appeared made of more wear-resistant materials - metal, ceramics, and polymers [2,3], as well as various combinations of them with cast iron [3]. Nevertheless, cast iron remains a very promising material with a number of serious advantages: relatively low wear and low cost of the material, ease of manufacture, independence of braking efficiency from weather conditions, etc.

When a locomotive runs 12-18 thousand km, cast iron brake shoes wear out to half their mass; thus, tens of thousands of tons of cast iron are irretrievably lost every year. In this regard, scientific research aimed at finding ways to increase the operational durability of cast iron brake shoes is relevant.

One of the most important tasks for railway rolling stock is to increase the reliability and durability of braking systems, which is associated with ensuring strength and increasing wear resistance of the shoe-type brake unit.

A significant disadvantage of the shoe brake is that when the wheelset moves at high speeds and the braking distance is reduced, it is necessary to create a significant braking force, which leads to wheel skidding, i.e., movement of the wheelset without its rotation [4-6].

In addition, problems arise during operation related not only to increased wear of the pads, but also to damage to the associated wheel pair bandages. This is often due to poor-quality manufacturing of the pads. At the same time, an important quality of the friction material used is its compatibility with the steel bandage, eliminating its damage.

Research analysis. One of the main conditions imposed on the main elements of brake units is the requirement for high frictional heat resistance, i.e., the ability to maintain certain values of the friction coefficient and the minimum amount of wear of the rubbing pair in the optimal range of speeds, temperatures, and loads.

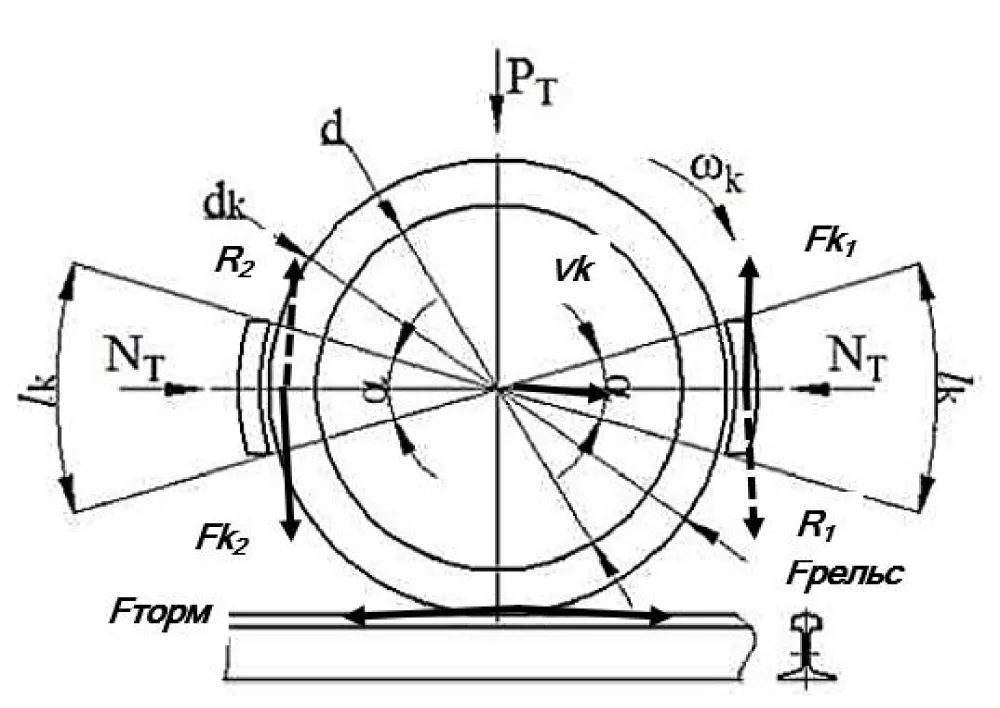

With wheel-shoe braking, the braking force is created by radial pressure of the brake shoes on the wheels of the rolling stock. The mechanical action of the brake shoes on the wheel pairs is accompanied by frictional wear of the surface of the wheel rolling circles and the shoes themselves. The pressure of the brake shoes on the wheel pairs is two-sided [3,6]. The calculation scheme for the quasi-static calculation of the loading of a locomotive wheel pair during wheel-shoe braking is shown in Figure 1.

The following designations are introduced in the calculation scheme of Figure 1:

NT- the force of pressing the brake shoe on the bandage;

dk – diameter of wheel

Fk1 and - friction forces arising when the brake shoe presses on the bandage with a force, while the sign changes depending on how the brake shoe is located (in front or behind the wheel in the direction of travel), which can be calculated using the formulas Fk2 NT.

Where φk - is the coefficient of friction of the shoe on the bandage; it depends on the type of the brake shoe, as well as on the speed of the train and the specific pressure of the shoe on the wheel [4,5]. To exclude the dependence of the friction coefficient on the pressing force, the conventionally accepted calculated brake pressure NTP is used when performing brake calculations. The coefficient of friction for the calculated pressure is called the calculated coefficient of friction φkp. As the train speed decreases, the coefficient of friction increases. The values of the calculated pressure for different types of locomotives, cars, and their loading, shoe material are given in the tables; the values of the calculated coefficients of friction are calculated for speed intervals [4,5].

The friction force Fk1 is balanced by the reaction R1, which occurs on the brake shoe, and the friction force Fk2 is balanced by the reaction R2. These reactions, R1 and R2, are transmitted through the brake shoes and brake suspension to the frame, then to the spring suspension, and through it to the axle boxes and to the axles. At the same time, the reactions R1 and R2, together with the forces Fk1 and Fk2, create additional moments M1 and M2, unloading or loading the wheel depending on how the brake shoe is located (in front or behind the wheel in the direction of travel). The force of adhesion of the wheel to the rail is calculated using the formula FRAIL.

Where PT– load from the wheel to the rail;

Ψ– coefficient of adhesion between the wheel and the rail.

Under normal conditions, the reactive force FTORM of braking (braking force) and the force of adhesion of the wheel to the rail FRAIL are equal to each other and mutually balanced (Figure 1), and it is obvious that

In this case, the braking force cannot be increased indefinitely, since its value is limited by the inequality.

i.e., at any moment in time, the braking force FTORM cannot exceed the force of adhesion of the wheel to the rail FRAIL.

In this case, jamming of wheel pairs, or skidding, is possible, in which the wheel stops rotating and slides along the rail while the train continues to move. As a rule, jamming of wheel pairs does not occur instantly; it is preceded by its slippage, as a result of which the speed of the wheel pair becomes less than the forward speed of the rolling stock unit. This leads to an increase in the braking force FTORM due to an increase in the friction coefficient φk and jamming. In this case, at the point of contact of the wheel with the rail, kinetic energy is intensively converted into heat, and due to abrasion and the effect of high temperature on the surface, a slider (oval platform) is formed on the rolling surface of the wheel. This phenomenon is characterized by a characteristic shift of metal at the place of formation of the slider.

To prevent skidding during braking, the permissible braking pressure (braking force) is taken such that the friction force arising when two brake shoes are pressed on the bandage with a force of NT-FTORM = 2φk NT exceeds the adhesion force FRAIL= ψ PT (Figure 1).

The braking force FTORM is limited by the coefficient of adhesion of the wheel to the rail ψ. To ensure skid-free braking of the locomotive wheel pair, the following condition must be met:

Where n is the number of pads on the wheel (usually n = 1 or n = 2). The pressure of the brake pads on the wheel pairs is two-sided; therefore, in our case, n = 2 [3,6] (Figure 2.1);

ϕkp– the calculated coefficient of friction of the shoe on the tire; it depends on the type of brake shoe, as well as on the speed of the train and the specific pressure of the shoe on the wheel;

Σ NTP- total calculated force of pressing of brake pads on the axle, kN (tf);

Ψp- calculated coefficient of wheel-rail adhesion;

PT– axle load on rail, kN (tf).

Figure 2 shows the curve of the change in braking force FTORM during wheelset lockup.

The ratio of the total calculated pressure to the weight of the train is called the calculated braking coefficient.

where -is the calculated braking coefficient;

Р- weight of the locomotive;

Q -is the weight of the train cars.

The estimated braking coefficient characterizes the train's provision of braking pressure. The value of braking pressure per 100 t of train weight is numerically equal to the estimated braking coefficient, expressed as a percentage. The train must be provided with braking pressure according to the standard for its category [1,3].

In calculations where the use is taken into account emergency braking, the calculated braking coefficient is taken to be equal to its full value. If the application of full service braking is taken into account, the calculated braking coefficient is taken to be equal to 0.8 of its calculated value [3,7-16].

Conclusion

- The value of the coefficient of the brake shoe to the bandage depends on the material from which it is made, the speed of the train, its specific pressure on the bandage, the condition of the rubbing surfaces of the shoe and bandage, its shape, and the method of manufacture jk.

- The relationship between φk, V, and NT is determined experimentally in laboratory or operational conditions. It has been established that the value of φk decreases with increasing speed V and with increasing shoe pressure on the tire NT. For this reason, two-way wheel braking (Figure 1) gives a higher friction coefficient than one-way braking, since with the same force of pressure on the axle PT, the pressure on one shoe NT during two-way braking is two times less.

References

- transport. Moscow: Marshrut; 2006;392.

- Dankovtsev VG. Maintenance and repair of locomotives. In: Chetvergov VA, Kiselev VI, editors. Moscow: GOU “Teaching-Methodical Center for Education in Railway Transport”; 2007;4:14-17.

- Ibragimov MA, Kiselev VI, Ramlov VA, Skalin AV. Dynamics of locomotives: textbook. Moscow: RGOTUPS; 2005. 128 p.

- Inozemtsev VG, Kazarinov VM, Yasenev VF. Automatic brakes. Moscow: Transport; 1981. 464 p.

- Biryukov IV, Savoskin AN, Burchak GP, Serdobintsev EV, L’vov NV, Korotenko ML, Rybnikov EK, Derkach BA. Mekhanicheskaya chast tyagovogo podvizhnogo sostava [Mechanical part of traction rolling stock]. Moscow: Transport Publ.; 1992.

- Glushchenko AD, Faizibaev SS, Khromov SA. Model and numeric investigation of impulse contact fields of interface layers. WIT Transactions on Modelling and Simulation. 2001;27. Available from: https://www.witpress.com/elibrary/wit-transactions-on-modelling-and-simulation/27/3153

- Kasimov OT, Mamaev ShI, Grishenko AV. Causes of rolling stock brake equipment failures. Technical Science and Innovation. 2021;2:Article 9. Available from: https://btstu.researchcommons.org/journal/vol2021/iss2/9/

- Fayzibayev ShS, Khromova GA. Optimization of wheel and rail operation by reducing contact stresses during the dynamic interaction of rolling stock wheelsets. Tashkent: Fan va texnologiya; 2015. 180 p. ISBN: 978-9943-975-96-5.

- Fayzibayev ShS, Kasimov OT. Modeling the shift of the surface layer of the locomotive's wheelset bandage in the contact zones with the cast iron brake pads. Universum Tech Sci. 2020;(6):6.

- Calculation for evaluating temperature fields in the bandage material during braking of the UZTE16M diesel locomotive. Universum Tech Sci. 2022;(4):5.

- Khamidov OR, Kamalov IS, Kasimov OT. Heat calculation of pads during locomotive braking. AIP Conf Proc. 2023;2612(1):060019. Available from: https://pubs.aip.org/aip/acp/article-abstract/2612/1/060019/2880605/Heat-calculation-of-pads-during-locomotive-braking?redirectedFrom=fulltext

- Khamidov OR, Kamalov IS, Kasimov OT. Diagnosis of traction electric motors of modern rolling stock using artificial intelligence. AIP Conf Proc. 2023;2612(1):060018. Available from: https://pubs.aip.org/aip/acp/article-abstract/2612/1/060018/2880597/Diagnosis-of-traction-electric-motors-of-modern?redirectedFrom=fulltext

- Mamayev S, Fayzibayev S, Djanikulov A, Kasimov O. Method of selection of mainline locomotives in the unloaded state according to the speed characteristics affecting the electromechanical vibrations of the WMB. AIP Conf Proc. 2022;2432(1):030105.

- Kasimov O, Fayzibayev S, Djanikulov A, Mamayev S. Numerical studies for estimation of temperature fields in bandage material during locomotive braking. AIP Conf Proc. 2022;2432(1):030025. Available from: https://ui.adsabs.harvard.edu/abs/2022AIPC.2432c0025K/abstract

- Kasimov OT, Djanikulov AT, Mamayev SI. Modeling the bending of the tire surface by pads during braking. AIP Conf Proc. 2021;2402(1):070030. Available from: https://doi.org/10.1063/5.0074483

- Djanikulov AT, Mamayev SI, Kasimov OT. Modeling of rotational oscillations in a diesel locomotive wheel-motor block. J Phys Conf Ser. 2021;1889(2):022017. Available from: https://doi.org/10.1088/1742-6596/1889/2/022017

Save to Mendeley

Save to Mendeley